- Quality policy

- Quality control framework

- Improving customer satisfaction

- Communicating with customers

Relationships with customers

Basic approach

Nichiden’s services involve getting the right orders from customers and delivering them the right products. We see these services as an aspect of quality, and we work to boost this quality while earning customers’ trust. Reflecting this approach, we’ve earned ISO 9001 certification, and we’re working to improve both quality and customer satisfaction.

(Scope of periodic certification: West ME System Department, West Logistics Center, Techno Center)

Quality policy

Nichiden is a general trading company that specializes in mechanical parts and systems. Considering our users’ needs, we fuse our expertise with cutting-edge technologies to create outstanding production facilities and systems. Our quality-assurance system ensures we offer services that customers can depend on.

- 1. We pursue services that satisfy customers.

- 2. We strive to improve operational quality by setting quality targets and reviewing our performance.

- 3. We abide by all relevant laws, regulations, and other agreements.

- 4. We instill our quality policy at all relevant company organizations.

- 5. We regularly review and improve our quality policy to maintain, improve, and standardize the system.

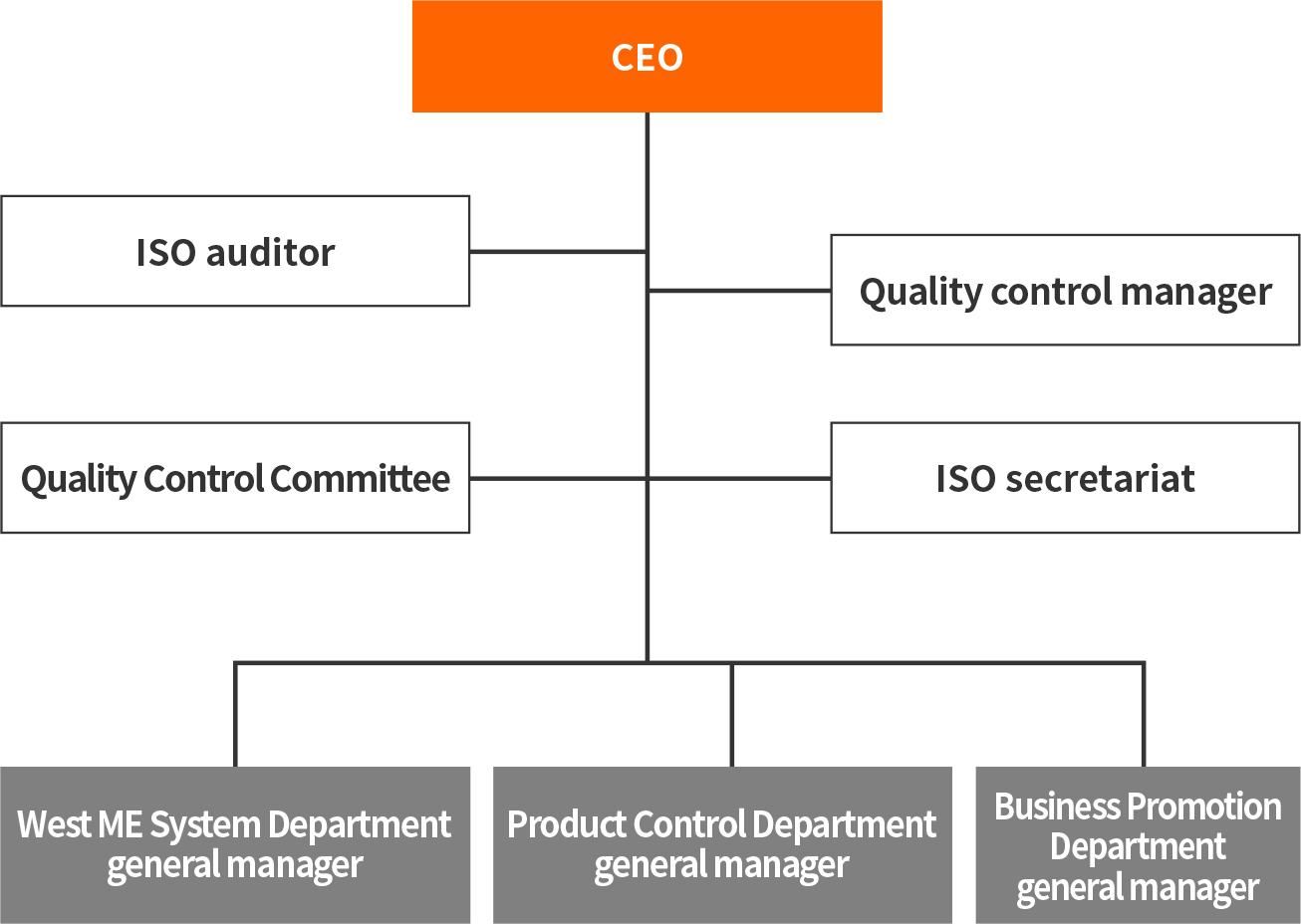

Quality control framework

Quality control implementation system

Nichiden’s services involve getting the right orders from customers and delivering them the right products. We see these services as an aspect of quality, and we work to boost this quality while earning customers’ trust.

Improving customer satisfaction

Structures for meeting customer needs in a timely manner

Reflecting our strong sense of mission to supply the products customers need, where and when they need them, we’re also committed to meeting customers’ expectations. To live up to that commitment, we operate facilities in each region and pursue new approaches to logistics by combining analyses and forecasts of region-specific market trends with close communication with suppliers. In addition, we work to supply products efficiently, quickly, and reliably by operating three logistics centers along with a network of second-tier logistics facilities throughout Japan.

East Logistics Center

Central Logistics Center

West Logistics Center

Techno Center: Fulfilling customers’ wishes

Our Techno Center consists of engineering teams that specialize in fabrication and setup. The Center’s responsibilities include cutting and machining linear guides as well as designing and assembling equipment such as systems that use aluminum frames and robot pedestals. It works to create new businesses in addition to shortening lead times.

Communicating with customers

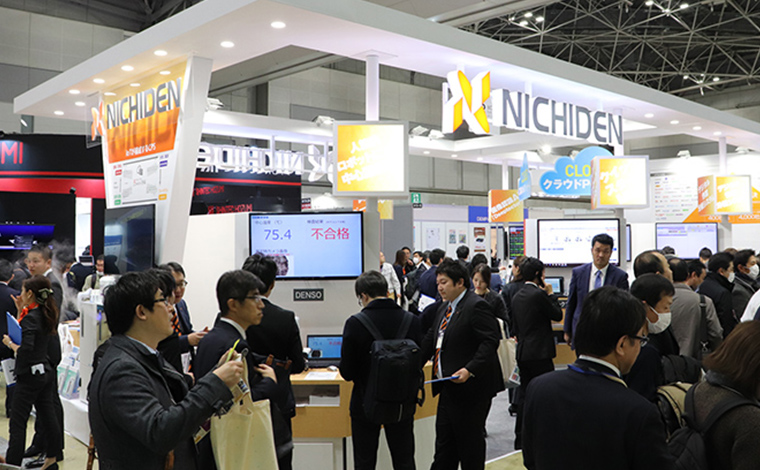

Talking face-to-face at exhibitions and seminars

We hold exhibitions where customers can talk directly to us about what matters to them. These give customers the opportunity to discuss their issues while looking at actual products on display. In addition, we hold MEKASYS, an exhibition hosted by individual sales bases, to create opportunities for large numbers of customers to try our products. The event attracts about 20,000 visitors every year.

Continuously communicating information to customers

We communicate a range of information to customers on an ongoing basis with the goal of helping them resolve issues and creating business for Nichiden. We offer information on a daily basis to accelerate customers’ businesses by, for example, publishing pamphlets detailing problem-solving that leverages our unique capabilities as a trading company, helping customers resolve issues through the MEKASYS website, and using social media and digital marketing.

MEKASYS website

Nichiden social media

Employee education

The West ME System Department, West Logistics Center, and Techno Center, which have earned ISO 9001 certification, hold annual workshops. In addition, by making the improvement of operational quality a goal of our medium-term business plan, we work to improve customer satisfaction while visualizing progress towards quality improvement on a quarterly basis.